Electrotherapy Industry

As a premier provider of world class PCB services, at Elmgrove Technologies, we specialize in providing unmatched customer service and flexibility. With well over 40 years in the industry, we understand all too well that poor quality or defective PCBs can negatively affect a production schedule. For this reason, we provide complete PCB repair services that are geared to meet the last minute nature of these issues.

In the project highlighted here, we helped a medical device company who had recently received their newly designed boards from an overseas manufacturer, only to find out the units were found to be faulty during field testing. Utilizing our in-house resources and our network of trusted partners, we were able to develop and streamline a repair process that ensured the boards were repaired and released back into service with minimal disruption to the customer.

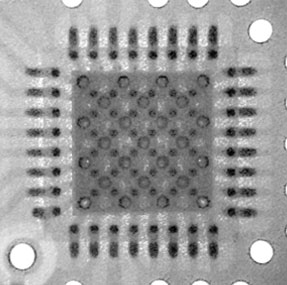

Each PCB required extensive rework and repair, including rerouting traces via cuts, lifting pins, and running electrical jumpers for new circuits. We also removed and replaced several ball grid arrays (BGA) and quad flat no leads (QFNL). Finally, all boards were X-rayed in order to investigate soldering voids left behind by the original manufacturer. In addition, we provided IPC-A-610 Class II inspections and ensured that all units were in full compliance with J-STD-001 and IPC-7711/7721 B assembly standards.

To learn more about this project, or the processes and resources used to complete it, see the table below or contact us directly.